| ||

| ||

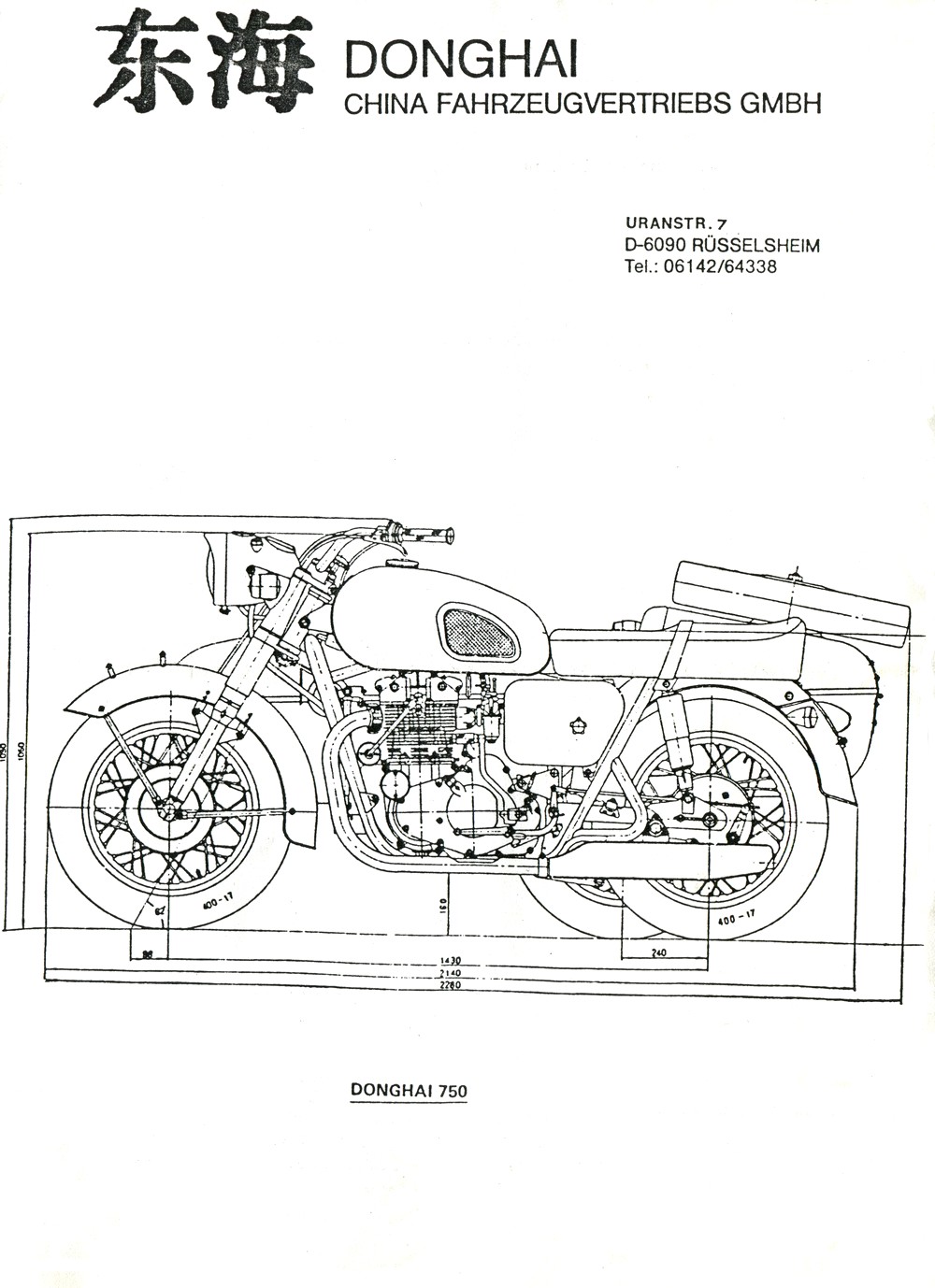

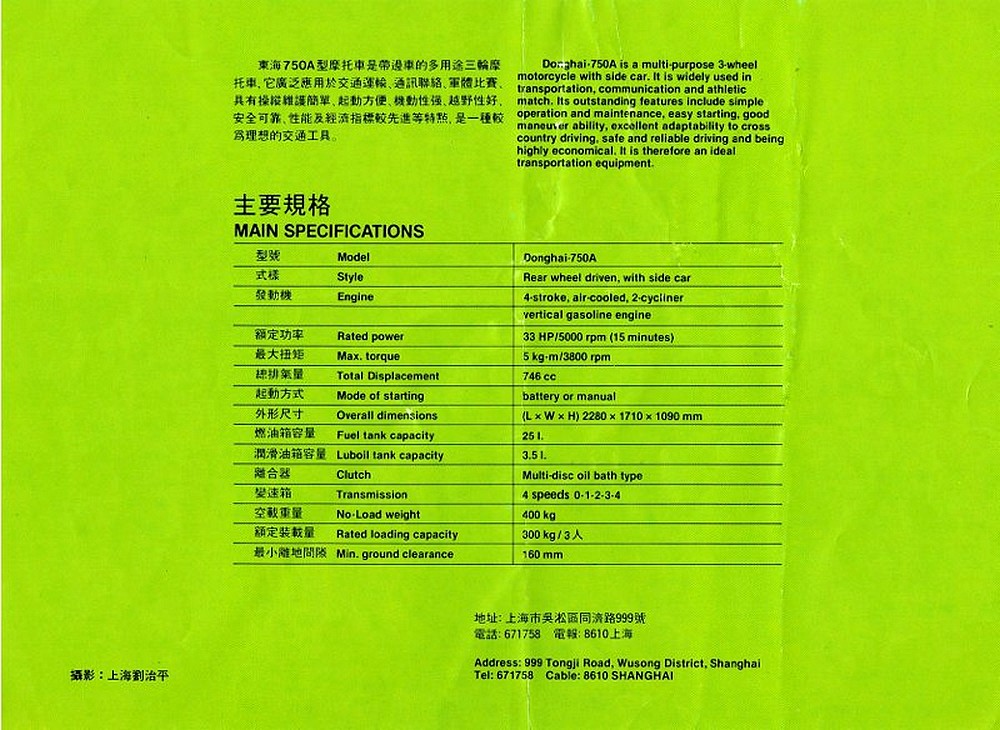

| DONGHAI SM 750/750 A | ||

| Publicaties | ||

| ||

| ||

| ||

| ||

| ||

| ||

| ||

| ||

| ||

|

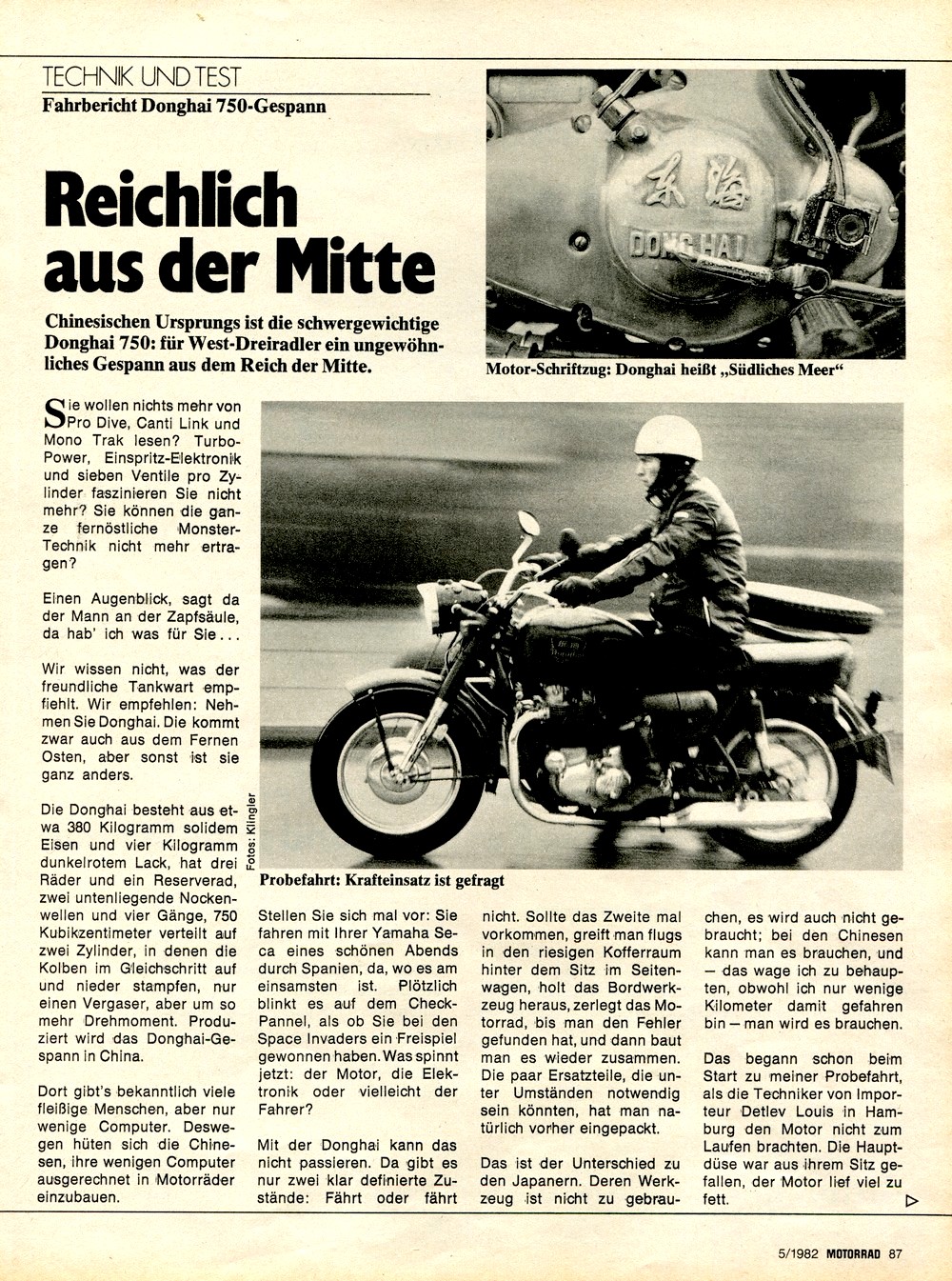

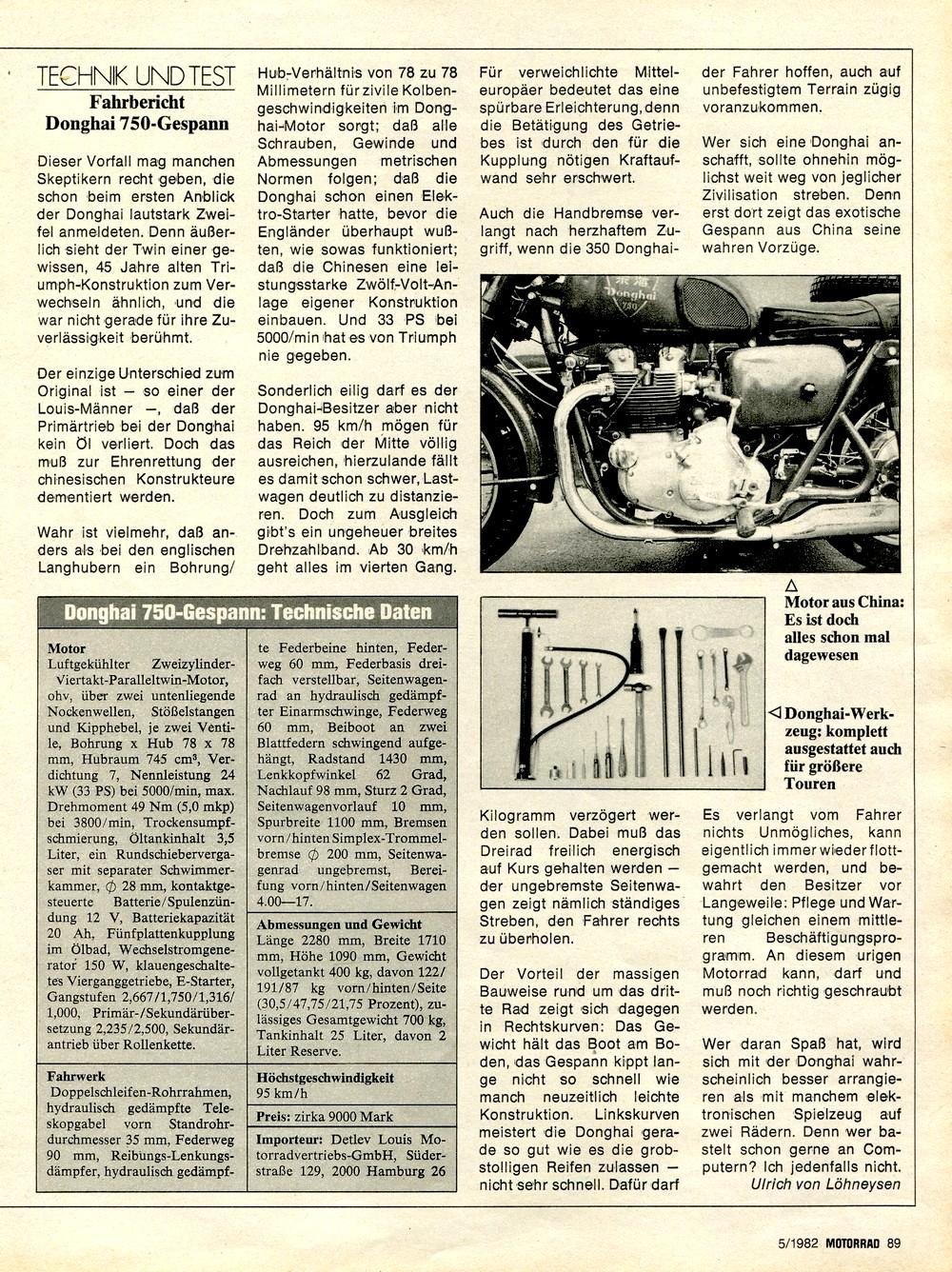

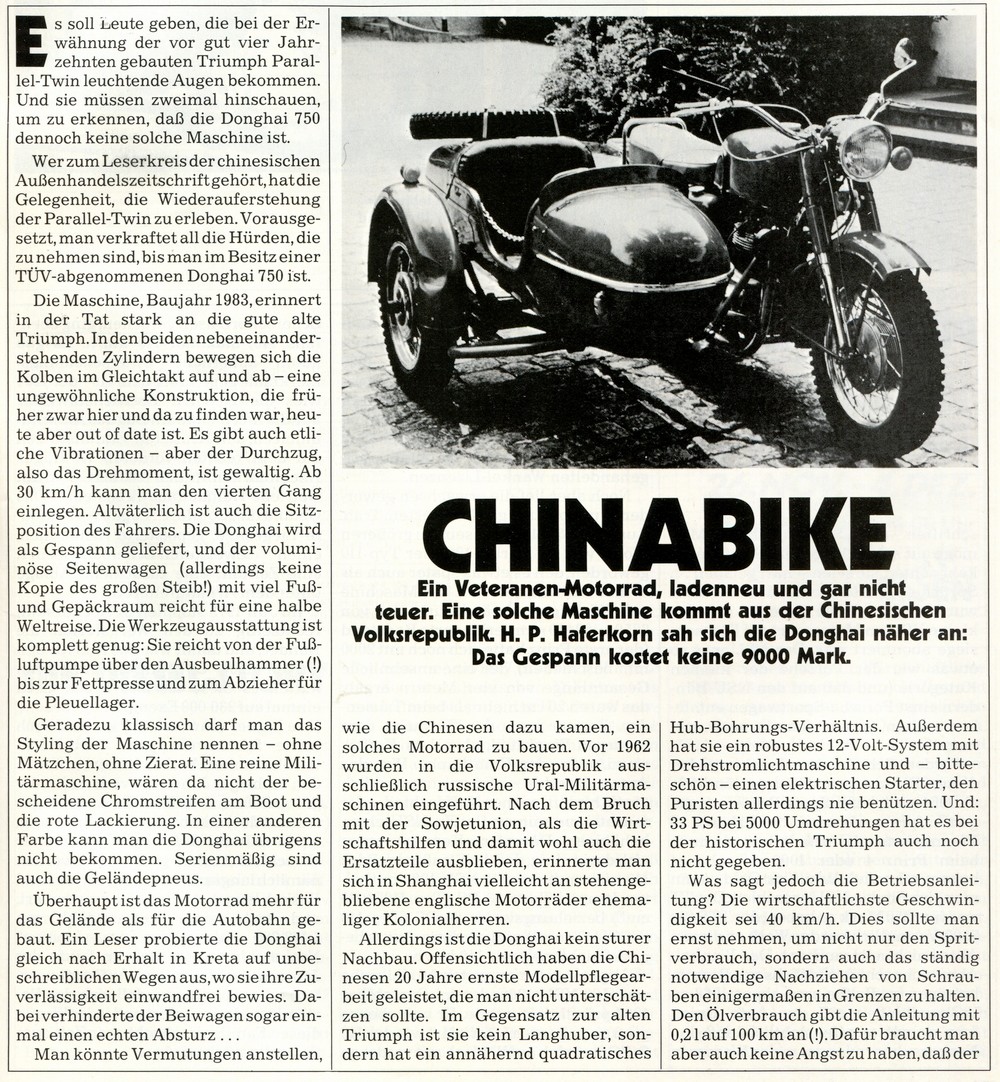

Translated by Google: Don't you want to know more about Prodive Canti Link and Mono Trak? TurboPower, injection electronics and seven valves per cylinder no longer fascinate you? Can you stand all the monsters from the Far East any longer? Just blink your eyes (says the cheerful man at the gas pump, I have something for you... We don't know what the friendly gas station attendant recommends. We recommend: Take a Donghai. It also comes from the Far East, but otherwise it is completely different. The Donghai consists of 380 kilograms of sturdy iron and four kilograms of dark red paint, has three wheels and a spare wheel, two underlying camshafts and four gears. 750 cc divided over two cylinders in which the pistons pound up and down simultaneously, only one carburetor, but the more torque. The Donghai with sidecar is produced in China. As is known, there are many hard-working people there, but only a few computers. That is why the Chinese are careful to put their few computers in motorcycles. Imagine this: you On a beautiful evening you are driving your Yamaha Seca through Spain, where it is the most lonely place. Suddenly the check mark flashes as if you have won a free game on Space Invaders. What is wrong now: the engine, the electronics or the driver? That can't happen with the Donghai. There are only two clearly defined states: driving or not driving. If the second situation arises, you quickly reach into the huge trunk behind the seat in the sidecar, take out the on-board tools, disassemble the motorcycle until you find the fault and then we put everything back together. Naturally, the few items that might be needed were packed in advance. This is the opposite of the Japanese. Their tools are not easy to use nor really necessary; With the Chinese you can use it, and I dare say that, even though I have only driven a few kilometers with it. It started at the start of my test drive, when the mechanics of importer Detlev Louis in Hamburg could not get the engine to work. The main jet had fallen out of its seat and the engine was running too rich. | ||

| ||

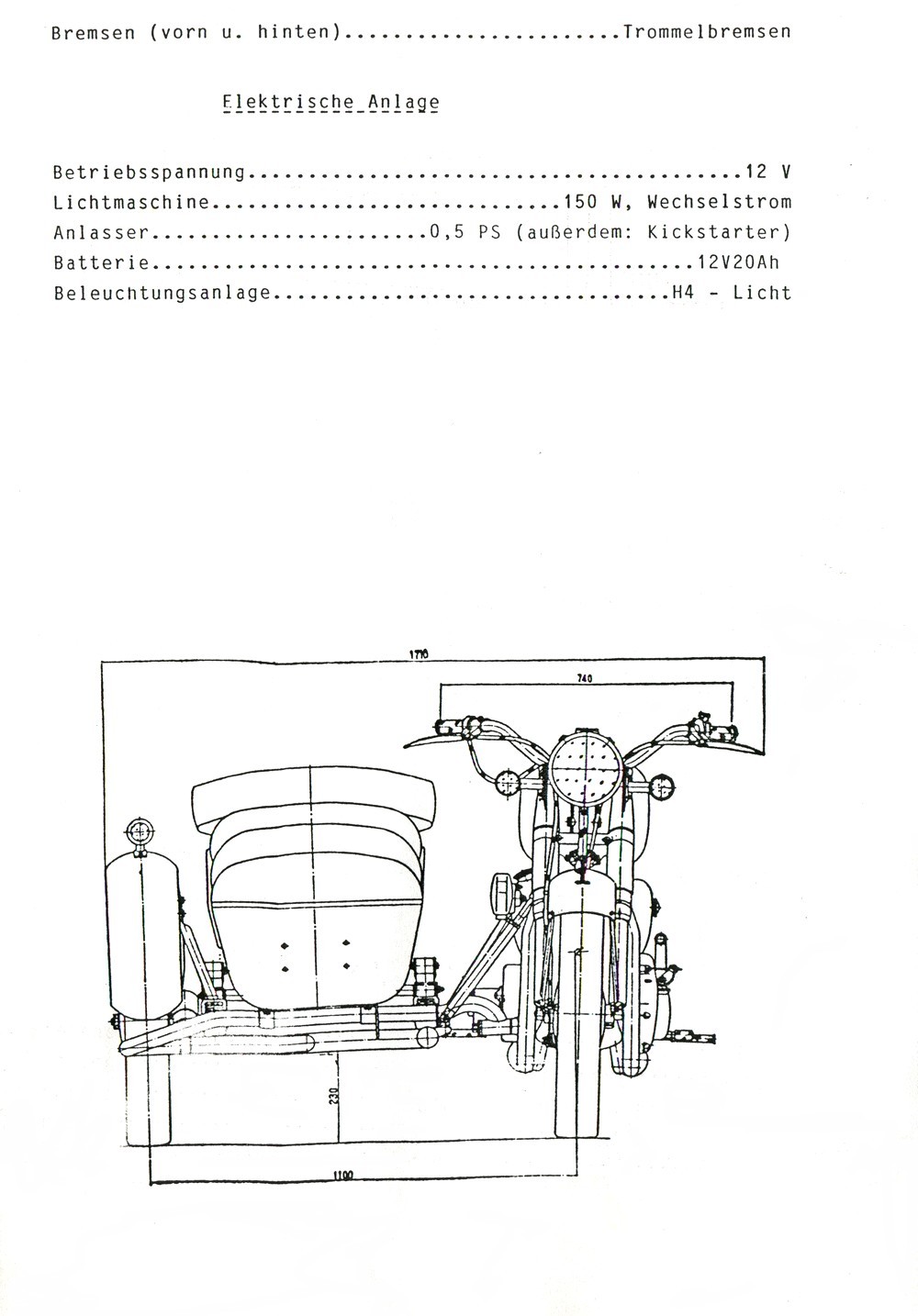

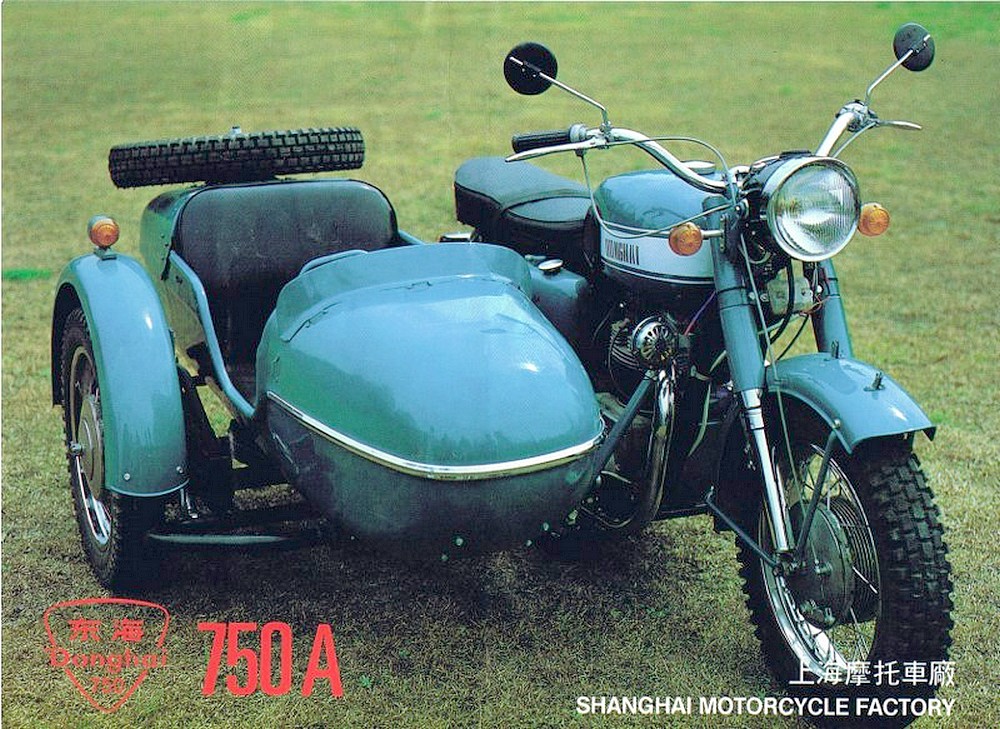

| Dit incident zou wel eens terecht kunnen zijn voor sommige sceptici die luidkeels hun twijfels uiten toen ze de Donghai voor het eerst zagen. Van buiten lijkt de Twin op een 45 jaar oud Triumph ontwerp, en hij stond niet bepaald bekend om zijn betrouwbaarheid. Het enige voordeel (zegt een van de Louis-mannen) is dat de primaire aandrijving van de Donghai geen olie verliest. Maar dit moet worden ontkend om de eer van de ontwerpers te redden. Het is eerder waar dat het anders is en de lange slagen zorgen voor een boring/slagverhouding van 78 tot 78 millimeter De gewone zuigersnelheden in de Donghai motor zorgen er voor dat alle schroeven, schroefdraad en afmetingen normen volgen. De Donghai al een elektrische starter had voordat de Britten überhaupt wisten hoe zoiets werkte. Dat de Chinezen een krachtig twaalfvolt systeem naar eigen ontwerp installeren. En Triumph produceerde nooit 33 pk bij 5000 tpm. Maar de Donghai-eigenaar kan geen haast hebben. 95 km/u is voor het Middenrijk misschien ruim voldoende, maar in dit land is het voor vrachtwagens moeilijk om afstand te houden en is er een ongelooflijk groot snelheidsbereik. Vanaf 30 km/u gaat alles in de vierde versnelling. Voor Midden-Europeanen betekent dit een merkbare verlichting, omdat de bediening van de versnellingsbak nogal zwaar is. kilo's moeten worden uitgesteld vanwege de inspanning die nodig is voor de koppeling. Uiteraard moet de driewieler op koers gehouden worden - dat is voortdurend te zien aan het ongeremde zijspan. Probeer de bestuurder in te halen. Het voordeel van de massieve constructie rond het derde wiel wordt echter duidelijk in bochten naar rechts: het voertuig wwn houdt het Qoot on the Bodas-team kantelt niet zo snel als sommige moderne constructies. De Donghai kan bochten naar links net zo goed aan als de grove banden dat toelaten - niet heel snel, maar de bestuurder mag hopen snel vooruitgang te boeken op het terrein. Iedereen die een Donghai koopt, moet sowieso proberen zo ver mogelijk weg te komen van welke beschaving dan ook. Alleen daar laat het exotische voertuig uit China zijn ware voordelen zien: het vereist niets onmogelijks van de bestuurder, kan daadwerkelijk steeds weer opnieuw op de weg worden gezet en beschermt de eigenaar tegen verveling: verzorging en onderhoud zijn vergelijkbaar met een middelgroot werkgelegenheids programma. Deze rustieke motorfiets kan, moet en moet nog steeds goed gedaan worden. Iedereen die ervan geniet, kan waarschijnlijk beter overweg met de Donghal dan met elektronisch speelgoed op twee wielen. Want wie houdt er van sleutelen aan computers? In ieder geval ik niet. | ||

| ||

| ||

|

The Chinese Donghai SM 750 is almost unknown in this country. An expert

explains to us the parallel twin of the Far East machine, which is

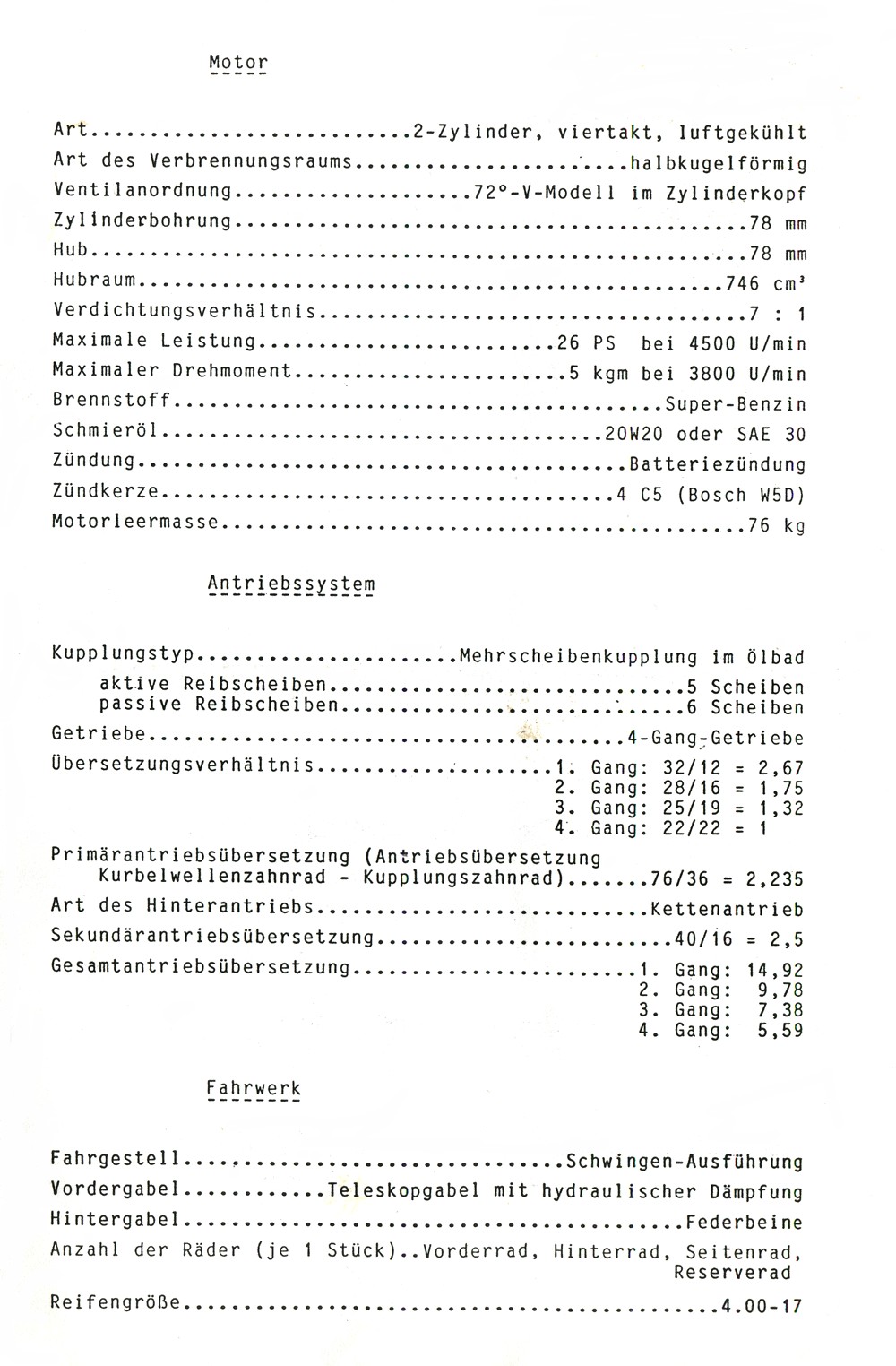

reminiscent of Triumph engines. Donghai? That's right, there was something there... In the eighties, Donghai SM-750 teams made in China appeared here for the first time. At first glance, the machines with the fantastic-sounding parallel twin are very reminiscent of the English “motorcycle building school”. But what about the second look? And what good is the Far East design? To be honest, it was pure coincidence that I came across the motorcycles from Shanghai in 1981 "I came across it," says Michael Flörsheimer. “At that time I was still working at the Rüsselsheim Industrial Museum - and there I came across a Chinese magazine that had an advertisement for the Donghai SM 750. I was particularly impressed by the aesthetic balance of the Donghai straight away - and I also thought that its 750 parallel twin must sound pretty good. So I wrote to the factory in Shanghai and asked how I could buy such a machine." About a year later, Flörsheimer was able to pick up his first Donghai in the port of Hamburg - which he then brought into German traffic on an individual basis. Then soon Since several people in their circle of friends really wanted to drive something like this, Marianne and Michael Flörsheimer quickly founded Donghai GmbH in Rüsselsheim in 1982. The small company imported around 60 Donghai teams into Germany from 1982 to 1988 and made them fit for use with sample reports and minor modifications local road traffic. “The SM 750 was produced from 1968 to 1985,” says the mechanic. “But until 1988 the factory still delivered machines from remaining stock. In total, around 27,000 copies of the SM 750 were built." But now it's high time we take a look at the engine in detail. The professional has already laid out the most important parts of the parallel twin. When we first look at it, we feel like it's a two-cylinder engine | ||

| ||

| remembered by triumph. “The Chinese certainly took their cues from this,” says Michael Flörsheimer. “But in many respects the engine also has completely unique design features. For example, the engine housing: the left half of the vertically divided housing houses both the crankshaft and the gearbox behind it . The right half of the engine housing, on the other hand, ends behind the crankcase. The gearbox is closed on this side by a separate cover. This has the advantage that you don't always have to open the gearbox when working on the engine and vice versa..." Next we look at it the one-piece crankshaft: its divisible connecting rods run on the crank pin with sliding bearings. A cast iron ring is screwed into the middle of the shaft as a flywheel. The shaft itself rotates in a ball bearing on the left and a plain bearing on the right. There is a gear on the right crank pin. It drives the two camshafts, which rotate below the cylinder block, via an intermediate gear. Intermediate tappets, bumpers and rocker arms transmit the cam movements to the valves hanging in the head. The rocker arms are located in separate housings that are mounted on top of the cylinder head. The inlet camshaft also drives the stamp oil pump. The fastening nut of the camshaft gear has an off-center drive pin on its front side - as soon as the camshaft rotates, it carries out an eccentric movement and thus drives the pump, which is located on the right half of the engine housing. “The motor has dry sump lubrication,” says the Donghai screwdriver. The pump works with two rams, one of which is responsible for the flow and the other for the return flow. The topic of flow: The pump first pushes the lubricant from the oil tank into the plain bearing bushing of the right crankshaft main bearing. Here it enters the hollow crankshaft and first lubricates the connecting rod bearings. Before that, however, part of the oil delivered is diverted via a channel in the right half of the engine housing and via a riser pipe | ||

| ||

| led to the cylinder head. The issue of backflow: The oil that flows through the engine collects at the bottom of the crankcase. Here it is sucked in, also via a channel in the right half of the engine housing, and conveyed back into the oil tank via an oil hose. “There is an oil pressure control switch where this hose is connected to the tank,” says practitioner Flörsheimer. “Inside it is a plastic insert with two holes through which the oil has to pass. The oil pressure pushes a spring-loaded metal cap upwards The ground connection of the oil pressure control lamp is interrupted, whereupon it goes out. So far so good. But if these engines are subjected to too much load for a long time, it can happen that the oil temperature becomes so high that the plastic insert literally begins to melt, and the holes in it practically start to melt collapse. The oil then no longer gets back into the tank - the lubrication breaks down. This is a central weak point, which in some cases also led to crankshaft damage. In order to eliminate this source of error, we made a replacement for the plastic insert from a more heat-resistant material." Let's now take a look at the power flow of the engine: There is a primary wheel on the left crank pin; it drives the clutch basket, which sits on the transmission input shaft behind it. The output shaft of the four-speed dog gearbox rotates behind the input shaft. “The gearbox is very robust. "I don't know of any problems with it," says the ex-importer. "The friction disks of the clutch are covered with cork - that's why you shouldn't use high-alloy oils in this engine, otherwise the clutch tends to slip." Next, Flörsheimer talks about the twelve-volt three-phase alternator. It has its own housing and is located in an extension of the right end of the crankshaft. It is driven by a special screw that is screwed into the right end of the crankshaft and has a groove on the front. The shaft of the Lima rotor engages directly in this groove. “Depending on the driving style, sooner or later it can happen that the groove in the screw widens due to load changes and the rotor shaft breaks as a result. To solve the problem, we made a special coupling piece and modified the rotor so that it is frictionally connected to it via a mounting cone." The battery ignition breaker contact is controlled by an actuating cam that sits on the left end of the exhaust camshaft. "One I never considered converting to contactless ignition on my own machine," says Flörsheimer. “Because with the breaker ignition, I’m sure I could fix it on the go. And finally, it is precisely this understandable technology that makes the machines so attractive for me." And the service life? The Donghai driver has now covered 30,000 kilometers with his own "first" machine and, with the exception of the oil pressure switch problem described, has not had any major problems . An astonishingly positive outcome - not only the doubters of yesteryear, who dared to make gloomy predictions when reading the first Donghai announcements in the motorcycle press, might think, but also large parts of the Dnieper and Ural community. And also one or two Triumph fans... | ||

| The ex importer. Together with his wife Marianne Flörsheimer, Michael Flörsheimer founded Donghai GmbH in 1982. There is practically no spare parts supply in China anymore, but the small Rüsselsheim company can still supply almost all spare parts for the Donghai SM 750 today. For example, a piston including rings and bolts costs 68 euros, while connecting rod bearing shells cost 12.80 euros per pair. | ||

| ||

| ||

| ||

| ||

| ||

| ||

| ||

| ||

| ||

| ...DONGHAI is not a well-known name from the classic motorcycle period. The only thing that is somewhat outdated about this Chinese-built 746 cm3 parallel twin-cylinder OHV machine is its construction, which could be transported – roughly – to the 1950s in central England. To assess this machine we have to put ourselves in the position of the Chinese, who have little choice when purchasing a heavy sidecar machine and are happy when this mass of heavy metal comes with 33 HP at 5000 revolutions per minute, can afford. It is certain that they also want to bring the Donghai to Germany. (may 1983) | ||

| ||

| ||

| ||

.jpg) | ||

.jpg) | ||

.jpg) | ||

|

STORY ( a bad translation) Made in China for several years. de Dongh is now (1982) available in Europe. to be precise in Hamburg, where our correspondent could not resist knowing how this girl from Changhai behaves towards her Japanese cousins. Much more refined. The Donghai, which sells for around 22,500 francs in Germany, is the first motorcycle produced in China, with a production rate of 20,000 units per year, which is far from negligible. But, you might say, who can buy a motorcycle in China? First of all, the army, which takes on the majority of the contracts. For individuals it becomes rarer because you have to know that the average salary of an employee hardly exceeds 150F per month. This is enough to live on, but there is no luxury, let alone a Donghai. Let us also emphasize that, by making a little calculation regarding production figures, we realize that we would have to wait about 3000 years before every resident of China would own their own motorcycle. We understand better why the few machines we see there often have entire families welcoming the bike, hence the interest in the sidecar formula offered on this machine. Dictated by a concern for thrift. The design of this motorcycle meets two requirements: reliability and ease of maintenance. In this way, it should always be possible to help in any area, as long as the user encounters a technician along the way. And old iron. the Donghai is not missing with its "sidecar", dry it weighs 400 kilos with a length of 2,280 m and a width of 1.70 m. On a pure level, aesthetically speaking, it resembles a beautifully restored old motorcycle. Evil tongues also say that it is a perfect replica of a 1938 Triumph that traveled the Asian circuits in the 1950s. It must be recognized that, in addition to its silhouette, its sound is reminiscent of the sounds of the good old British "twins". while the vibrations generously distributed through the controls give a very retro tone. In terms of performance it is not enough: the modest 33 hp that is delivered above 100 km/h (a good version from 1982 develops more than 80 hp and easily reaches 200). Despite this wise temperament on paper, the behavior of your Donghaf must be controlled by force of the wrist, under the influence of inertia sidecar, which has no linked brake, the front wheel shows the unfortunate tendency to deviate to the right with every deceleration. No problem in the right turns, the whole thing behaves like a go-kart, but on the right side you still have to use a good dose of energy to get on the right track. We are convinced of the sophistication and ease of management of more modern productions. But for once we don't get tired of the silent limitations imposed by mechanics, we appreciate having the time to contemplate the landscape with our noses in the wind. The importer, who has clearly identified the essence of this machine, even offers a very realistic garment as an option: a Barbour jacket. glasses like von Rithofen and a helmet in the same atmosphere. Reserved for a certain Chinese elite, this motorcycle is also a rich favorite in Europe... | ||

| ||

|

Een Donghai? Of Dong Hai? | ||

|

A Donghai? Or Dong Hai? by Dolf Peeters. Rare is only expensive if it is sought after. But there are gems that cost almost nothing if you have a bit of a free spirit. For example, this 750 cc Donghai/Dong Hai (plus its brother) were suddenly for sale. The asking price per piece was € 1750. And while I was dreaming away, they were sold. Fortunately, they ended up in good hands with goldsmith Ben van Helden and they can be visited. Just as Indian lost the government orders battle to Harley, Donghai missed the boat in China in the competition with Chang Jiang, the BMW/IMZ/KMZ clone from Russia. However, in China people also worked through all kinds of plan-economic approaches. This resulted in thousands of Donghai combinations being produced that were not even assembled. The possibly approximately 20,000 two-cylinder 750 cc pushrod machines were made between 1971 and 1984 and were very much inspired by BSAs and apparently had limited reliability. Depending on the source, the power was stated to be between 26 and 33 hp. Donghai stopped producing complete vehicles in 1984 and stopped producing parts in 1986, until the molds were finally destroyed in 1992. The editor – Ben has already covered the whole story on his site from the above info believes that the Donghai 750 represents an era of independent research and development in China and is a history of the Cultural Revolution. It's a bit disturbing and sad to end like this. Let's all miss Donghai SM750 together. There are reportedly 10 more in Shanghai. With thanks to Ben van Helden, also administrator of Bensbikes.nl | ||

|

This site is designed and made by Ben van Helden copyright on all pages |