|

|

|

|

Stil working on it

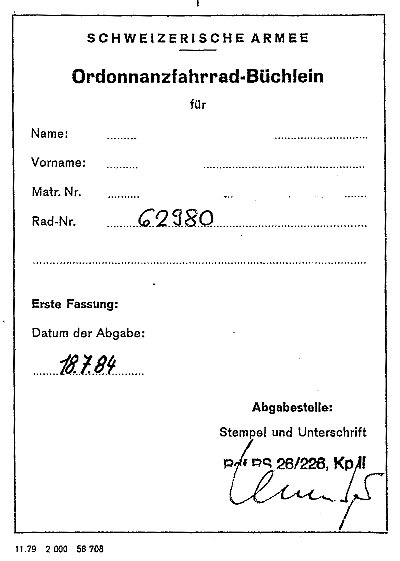

Hi Bicycle fans

in the English speaking parts of our small world. Specially for

you I did try to translate the German Manual of the military

"Ordonnanzfahrrad" user in the Swiss Army.

I did get a copy as PDF file and had

to make first TXT files from that one, page by page. Than I did

scan them back as readable PDF files and did some translation

with Microsoft Word. So it will not be perfect but who is?

Ofcourse it did not work this way. Any suggestion to make it better

is welcome. Hope you like it. Please help me to translate this.

Ben van Helden 2006

|

|

|

|

|

|

|

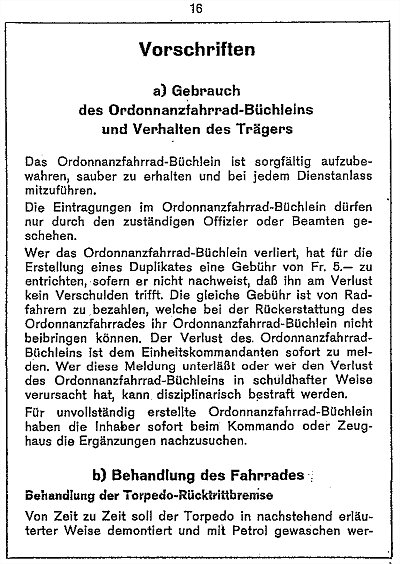

Regulations

a)

Use

of the Ordonnanzfahrrad-booklet

and behaviour of the user

The

Ordonnanzfahrrad booklet is to be kept carefully kept clean and

carry with each service cause.

The entries in the Ordonnanzfahrrad booklet may happen only by

the responsible officer or Officials .

Who looses the Ordonnanzfahrrad booklet, has to pay Fr. 5 for

the production of a duplicate, if it do not prove that at the

loss no being to blame for meets it.

Those same fee is to be

paid from cyclists to, who during the restitution of the

Ordonnanzfahrrad their Ordonnanzfahrrad booklet not to teach

know. The loss of the Ordonnanzfahrrad booklet is the commander

of unit immediately to announce. Who this message omits or who

the loss of the Ordonnanzfahrrad booklet in culpable Way caused,

can be disciplinarily punished. For incomplete provided

Ordonnanzfahrrad booklets have the owners immediately with the

command or To seek arsenal the additions restitution of the

Ordonnanzfahrrad their Ordonnanzfahrrad booklet not to teach

know. The loss of the Ordonnanzfahrrad booklet is the commander

of unit immediately to announce. Who this message omits or who

the loss of the Ordonnanzfahrrad booklet in culpable Way caused,

can be disciplinarily punished. For incomplete provided

Ordonnanzfahrrad booklets have the owners immediately with the

command or t seek arsenal the additions.

b) Treatment the bicycle

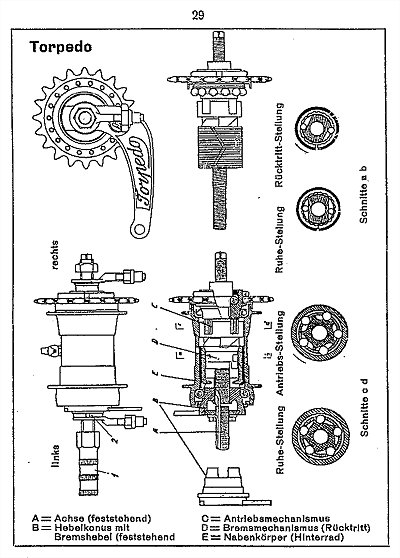

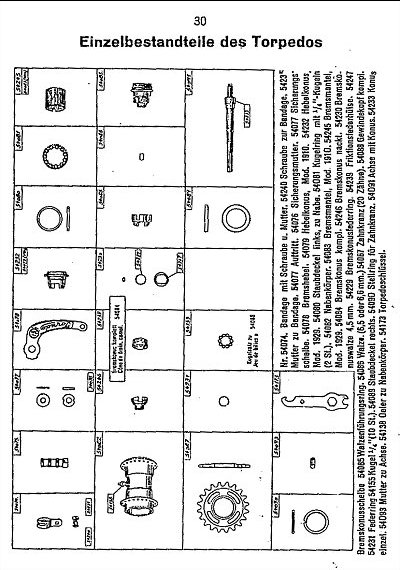

Treatment that Torpedo resignation brake

Occasionally that is torpedo in below described way dismantled

and with Petrol are washed

|

|

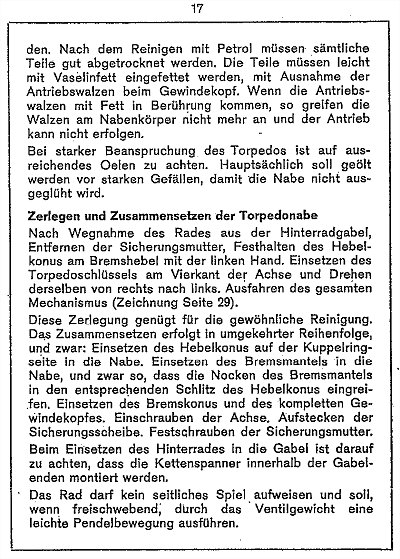

After the cleaning with Petrol all parts must well dried. The

parts must lightly greased with Vaseline, with exception of the

roll drives with the thread head. If the roll drives come into

contact with the fat, then the rollers at the hub body do not

seize no more on and the drive cannot take place.

In the case of strong demand the torpedo is to be paid attention

to sufficient oiling. Mainly is to be oiled before strong

downward gradients, so that the hub out one does not glow.

Divide and Build up for the torpedo hub

After removal of the wheel from the rear wheel fork removing the

locknut holding of the lever-konus at the brake lever with the

left hand. Begin the torpedo key at the square of the axle and

tricks of the same from right to the left. Drive out the entire

mechanism (drawing page 29)

This dismantling been sufficient for the usual cleaning building

up takes place in more in reverse sequence: Insert lever-konus

on the Cupola ring side into those Hub, so that the cams of the

break-shoes in the appropriate Slot lever-konus intervene.

Begin the break konus and the complete thread head. Screw in for

the axle. Attach the lock washer. Bolt on the locknut.

When inserting the rear wheel into the fork it is to be made

certain that the chain tensioned within the fork ends to be

installed.

The wheel may not do lateral play exhibit and is, if freely

floating by the valve weight an easy oscillating motion

implement.

|

|

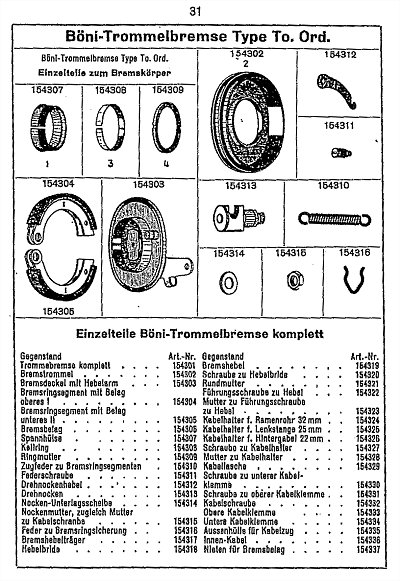

Treatment of the <<B÷ni>> drum brake.

The brake lining is to protect for oil and fat and is not to be

touched with greasy fingers.

to catch flowing oils from the Torpedˇ hub, is inside the

brake cover a oil catch ring attached, which prevents that oil

reached the brake shoes.

By in

Brake cover within oils fang struggle existing hole

is possible penetrated oil outward led become. It is to be made

certain therefore that this hole is not clogged.That oil catch ring fulfilled however only his purpose, if the

torpedo hub reasonably lubricated, D. h. not with oil one

inundates.

The drum brake is up no case to oil or too greasy

oiled brake linings brake-badly and Óll1 best are replaced by

new.

Temporarily ever nevertheless that can Drain on hot oren

remedy create, open fire may however not to be used. The brake

whistles then is this an indication that it oiled.

Disassembly and assembly of the

"B÷ni" drum brake

The dismounting happens in the following way:

first loosen the nut and remove it. Here the box spanner is

to be used. Laest the annular nut do not separate in such a way

help some light bevel rojt the brass essay on the plan page that

Annular nut.

After the annular nut, strikes one is distant for

that easily with that Mallet on the edge of drum to the drum

jumps off. Installing, whereby correct sticking of the drum on

the torpedo hub to reach is seems, in the following way: |

|

Press the adapter sleeve (1) with the

screwed-in thread over the left torpedo hub end. Then slide the

drum (2) over it and make sure that it rests well on the back.

Place the wedge ring (3) with the

thin part in between the drum and the clamping sleeve so that

the slots of the wedge ring and the clamping sleeve are offset

from one another. The wedge ring is to be pressed in until the

thread for the ring nut is released, but to push in the wedge

ring no breakthrough etc. to use. Now screw on the ring nut (4)

and tighten with socket wrench.

Now you control how the drum is

running, i. whether it does not wobble sideways. If this is the

case, it should be aligned with the mallet.

Using the

hammer and brass attachment, lightly beat around on the flat

side of the ring nut so that the wedge ring is firmly pressed

in. Then the ring nut again by means of plug connections!

Attract. This process is repeated several times until the drum

is firmly seated.

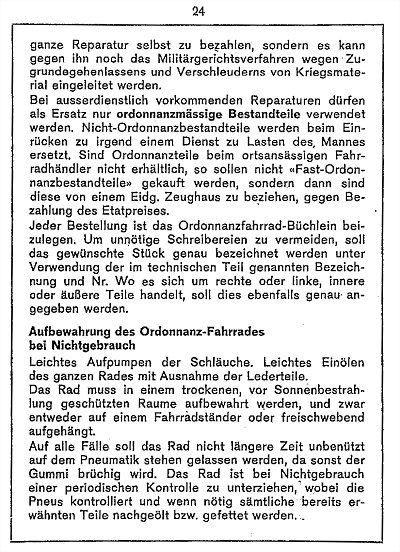

Disassembly and assembly of

the handlebar and steering

Handlebar:

1.Loosen the nut on the brake

linkage with a key.

2.Loosen the clamping screw (several

passages) with a key.

3.Loosen the clamping cone by pressing

down the clamping screw.

4.Pull out the handlebar. |

|

Control:

1. Remove the

head tube nut with key.

2. Remove the lantern holder.

3. Remove the upper control cone

4. Remove the upper ball set.

5. Lift the frame by approx. 9 cm.

6. Remove the lower ball set.

7. Extending the fork.

The assembly takes place in reverse

order.

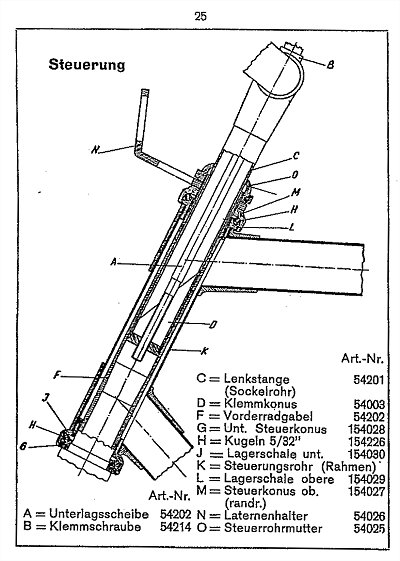

Disassembly and assembly of the front hub

1. Loosen the nuts G with a key.

2. Remove the dust rings B with a key.

3. Remove left cone C with key.

4. Extending the axle In Ó direction.

The assembly takes place in reverse

order.

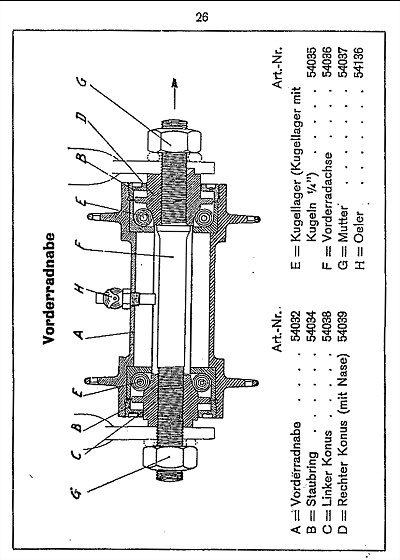

Disassembly and assembly of the bottom bracket.

1. Loosen the left crank key.

2. Remove the crank.

3. Release the left dust cover with

key (left-hand thread).

4. Remove the lock washer.

5. Remove the left cone with key

(left-hand thread).

6. Extend the axis in ---> direction.

The assembly takes place in reverse

order.

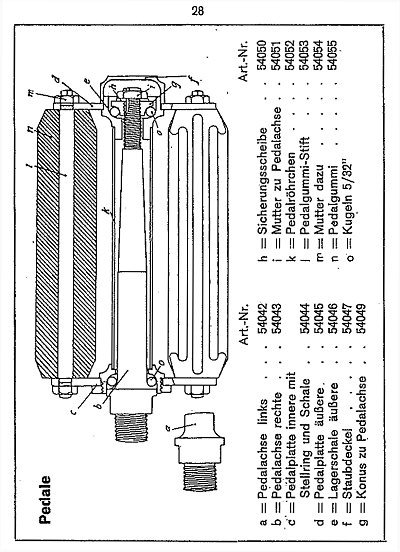

Disassembly and assembly of the pedals

1. Remove the dust cover.

2. Remove the axle nut.

8. Remove the lock washer.

4. Remove the cone. |

|

5. Remove the pedal.

The assembly takes place in reverse

order.

Treatment of the orderly bicycle

The meticulous maintenance of the bike

is a natural duty of every cyclist. All repairs that become

necessary as a result of careless handling are at the expense of

the defective.

Parking service - Regulations for

bicycles.

The different parking service ticket

1st march park service (MPD)

Check the readiness to march before

starting the ride and keep holding Create the readiness to march

after finishing the drive. Approximately 5 minutes.

2. Maintenance Service (UPD)

Cleaning and advanced control.

Depending on the condition, however, at least every 3 weeks. 2 -

2 Ż hours

3. Technical Parking Service (TPD)

Dismantling .. Cleaning, greasing

and mounting of the bearings (front hub, torpedo hub and pedals,

4 hours depending on the load on the bike.

1. The march park service a)

The verification of the march

readiness before the start of the journey and at the holding

consists of the following controls: |

|

to pay for the whole repair

itself, but it can still be instituted against him for the

military court proceedings because of letting go and the

squandering of war material.

For repairs that occur outside of

service, only substitutes may be used as substitutes. Non-order

components will be replaced upon entry into any service at the

expense of the man. Are ordonnanzteile not available from the

local bicycle manufacturer, so should not be purchased

Fast-Ordonnanzbestandteile but, then these are to be obtained

from an Eidg. Arsenal, against payment of the replacement price.

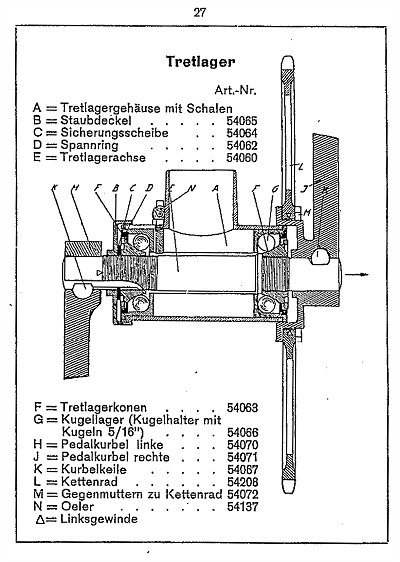

Each order must be accompanied by the

Ordonnanzfahrrad booklet. In order to avoid unnecessary

scribing, the desired piece should be exactly identified using

the name and number given in the technical part. Where this

concerns right or left, inner or outer parts, this should also

be specified.

Storage of the orderly bicycle when

not in use.

Easy inflation of the hoses. Lightly

oil the whole wheel except the leather parts. The bike must be

stored in a dry, protected from sunlight room, either on a

bicycle stand or suspended suspended.

In any case, the wheel should not be

left unused for a long time on the pneumatic, otherwise the

rubber will be brittle. The wheel should be subjected to a

periodic inspection when not in use, whereby the tires are

checked and, if necessary, all the parts already mentioned are

oiled or greased. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|